Free Classifieds at Hot-Web-Ads.com - View Item Content by ID 15448138

Hot-Web-Ads > Business Opportunities > Marketing & Sales > Item ID 15448138

Item ID 15448138 in Category: Business Opportunities - Marketing & Sales

Cannot view this item. It could be pending, expired or deleted.

Below item is randomly selected from the same category and may have similar content.

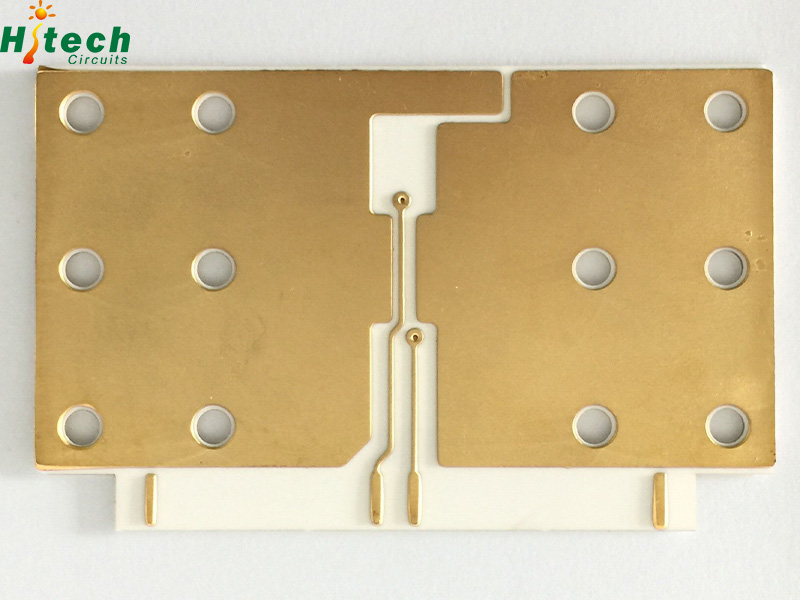

Ceramic PCB VS Aluminum PCB | |

The biggest difference between the ceramic PCB and the aluminum PCB is the material and structure. The ceramic PCB uses ceramic as the substrate material. In terms of structure, the insulation performance of the ceramic itself is very good, so the ceramic PCB does not need an insulating layer. The aluminum PCB is a metal-based copper clad laminate with good heat dissipation function. Generally, a single side pcb is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. For high-end use, it is also designed as a double-sided PCB board, and the structure is circuit layer, insulating layer, aluminum base, insulating layer, and circuit layer. Very few applications are using multi-layer boards, which can be formed by bonding ordinary multi-layer pcb boards with insulating layers and aluminum bases. The thermal conductivity of the aluminum PCB is almost between 1.0 and 2.0. It can be seen from the structure that the aluminum PCB has an insulating layer, so its thermal conductivity is mainly related to the insulating layer. The thermal conductivity of the aluminum PCB with an insulating layer is not outstanding, but much better than the general FR-4 PCB. At present, the ceramic PCBs on the market are mainly aluminum nitride ceramics and alumina ceramics. The thermal conductivity of alumina ceramics is almost 15~31, and the thermal conductivity of aluminum nitride is almost 135~175. Obviously, the thermal conductivity of ceramic PCB is much better than that of aluminum PCB. The insulating layer is the core technology of aluminum PCB, which mainly plays the role of bonding, insulation and heat conduction. The insulating layer of the aluminum PCB is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulating layer, the more conducive to the diffusion of heat generated during the operation of the device, and the more conducive to reducing the operating temperature of the device, so as to achieve the purpose of increasing the power load of the module, reducing the volume, extending the life, and improving the power output. In other words, the aluminum PCB performance is subject to the insulating layer. The ceramic PCB has no insulating layer, so there will be no such troubles.  | |

| Target State: All States Target City : All Cities Last Update : Nov 26, 2024 12:52 AM Number of Views: 10 | Item Owner : Alisa Contact Email: (None) Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

Hot-Web-Ads > Business Opportunities > Marketing & Sales > Item ID 15448138

© 2024 Hot-Web-Ads.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | USAOnlineClassifieds.com

2024-11-26 (0.418 sec)