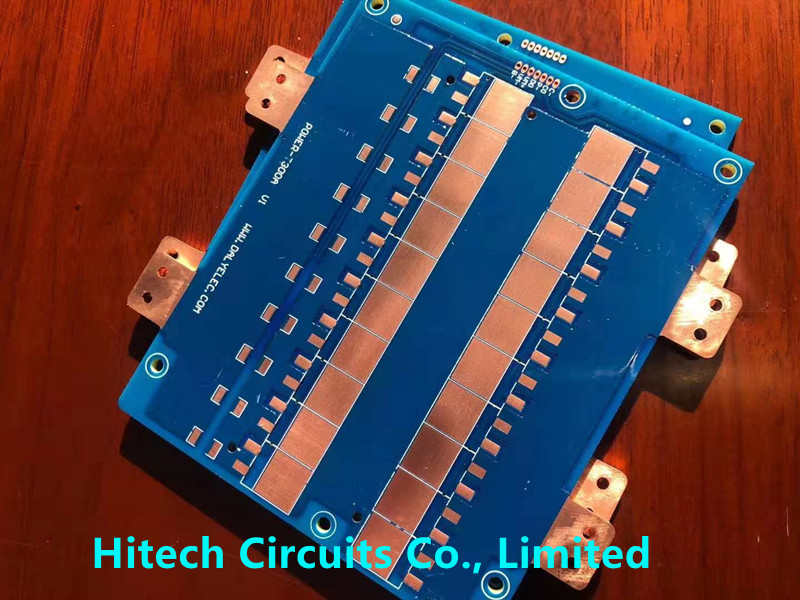

heavy copper PCB board (Business Opportunities - Marketing & Sales)

Hot-Web-Ads > Business Opportunities > Marketing & Sales

Item ID 15659042 in Category: Business Opportunities - Marketing & Sales

heavy copper PCB board | |

The application field and demand for thick copper plates have been rapidly expanded in recent years, and it has become a “hot” PCB variety with good market development prospects. The vast majority of heavy copper PCBs are high-current substrates (current x voltage = power). The main application areas of high-current PCBs are two major areas: power modules and automotive electronic components. Some of its main terminal electronic product fields are the same as conventional PCBs (such as portable electronic products, network products, base station equipment, etc.), and some are different from conventional PCB fields, such as automobiles, industrial controls, and power modules. High-current PCBs are different from conventional PCBs in terms of efficacy. The main function of a conventional PCB is to form a wire for transmitting information. The high-current PCB has a large current through it, and the main function of the substrate carrying the power device is to protect the current carrying capacity and stabilize the power supply. The development trend of such high-current PCB is to carry larger currents, and the heat emitted by larger devices needs to be dissipated. Therefore, the large currents passing through them are getting larger and larger, and the thickness of all the copper foils of the PCBs is getting thicker and thicker. The 6 oz copper thickness of the high-current PCBs manufactured now has become normal; The application areas of heavy copper circuit boards include: mobile phones, microwaves, aerospace, satellite communications, network base stations, hybrid integrated circuits, power supply high-power circuits and other high-tech fields.  | |

| Related Link: Click here to visit item owner's website (1 hit) | |

| Target State: New York Target City : All Cities Last Update : Jun 04, 2024 2:09 AM Number of Views: 83 | Item Owner : Alisa Contact Email: Contact Phone: +86 18126460264 |

| Friendly reminder: Click here to read some tips. | |

Hot-Web-Ads > Business Opportunities > Marketing & Sales

© 2025 Hot-Web-Ads.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | USAOnlineClassifieds.com

2025-04-20 (0.223 sec)