What’s the difference between Printed circuit board vs PCB Assembly? (Business Opportunities - Marketing & Sales)

Hot-Web-Ads > Business Opportunities > Marketing & Sales

Item ID 15876672 in Category: Business Opportunities - Marketing & Sales

What’s the difference between Printed circuit board vs PCB Assembly? | |

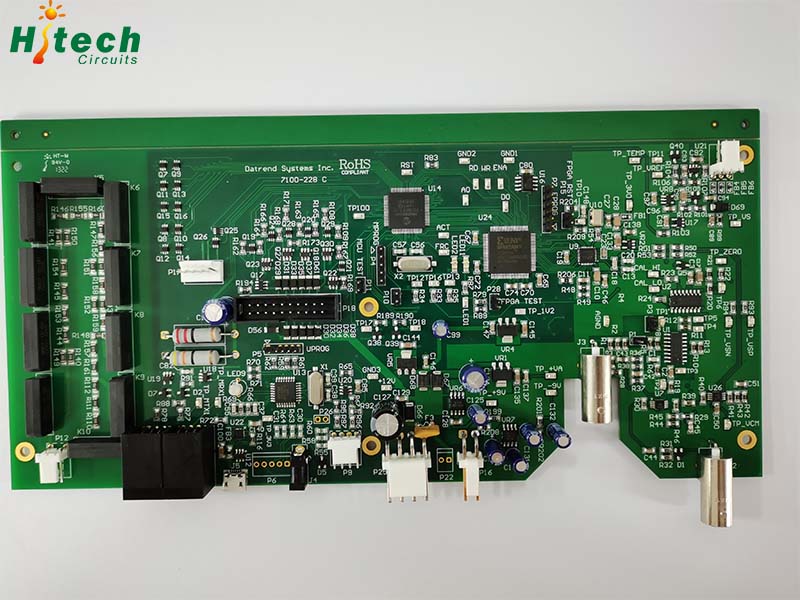

PCB is a printed circuit board because it is made by electronic printing, so it is called a “printed” circuit board. PCB is an important electronic component in the electronic industry, it is electronic base. It is the support of electronic components and the carrier of electrical connection of electronic components. PCB has been widely used in the production of electronic products. PCB Assembly generally refers to a processing flow, which can also be understood as the finished circuit board, that is, PCBA can only be counted after the processes on the PCB are completed. PCB refers to an empty printed circuit board with no parts on it. The above is the difference between PCB and PCBA. SMT (surface mounted technology) and DIP (Dual In-line Package) are both ways to integrate parts on the circuit board. The main difference is that SMT does not need to drill holes on PCB, but in dip, it needs to insert the pin into the drilled hole. SMT mainly uses the mounting machine to mount some micro and small parts on the circuit board. Its production process is PCB positioning, solder paste printing, mounting by the mounting machine, reflow oven, and inspection. The dip is a “plug-in”, that is to insert parts on the PCB board. It is a kind of plug-in integrated part when some parts are large in size and not suitable for mounting technology. Its main production processes are back glue, plug-in, inspection, wave soldering, plate brushing, and finished inspection.  | |

| Target State: All States Target City : All Cities Last Update : Dec 26, 2024 8:45 PM Number of Views: 48 | Item Owner : Alisa Contact Email: Contact Phone: +86 18126460264 |

| Friendly reminder: Click here to read some tips. | |

Hot-Web-Ads > Business Opportunities > Marketing & Sales

© 2025 Hot-Web-Ads.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | USAOnlineClassifieds.com

2025-04-01 (0.223 sec)