Challenge Confronted by Traditional PCB (Business Opportunities - Marketing & Sales)

Hot-Web-Ads > Business Opportunities > Marketing & Sales

Item ID 15901260 in Category: Business Opportunities - Marketing & Sales

Challenge Confronted by Traditional PCB | |

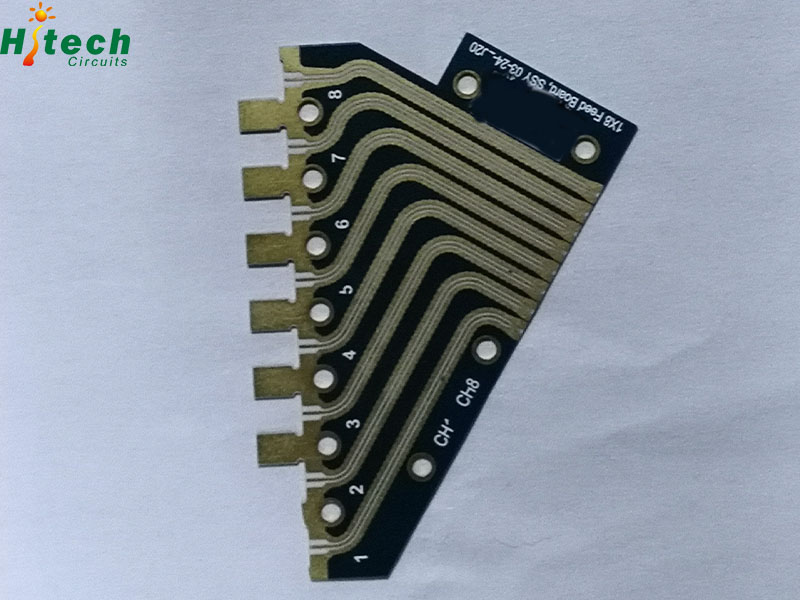

Fabricated in substractive process, traditional PCBs with organic laminates like epoxy, polystyrene and polytetrafluoroethylene as substrate material have been applied to participate in circuit assembly as early as latter half of 1950s. Even on the day when VLSI is widely applied, they are still applied to large extent. However, with the advent of SMT and constantly improving of semiconductor circuit integration, traditional PCBs have to face up with the following challenges when they are used in high-reliability electronic products. a. Heat Dissipation Challenge Along with increasingly wider application of VLSI and SMT development trend, organic laminated based PCBs are quite challenged by heat dissipation in terms of design, which results from low thermal conductivity of most ordinary PCBs. Nevertheless, ceramic features thermal conductivity that is 90 times of that of epoxy glass fiber, leading to excellent conduction cooling. Moreover, components on ceramic PCBs usually feature a lower junction temperature (Tj) than that on ordinary PCBs. b. CTE Compatibility Challenge SMT that became popular in the early half phase of 1980s is affecting the whole electronic assembly industry. Since SMT makes electronic components directly soldered onto both sides of PCB, compared with THT (through hole technology), SMT leads to lower cost and higher reliability. Furthermore, it makes it more accessible to implement automation and capable of reducing circuit size by five sixths. Some reliable packages, LCC (leadless chip carrier) for example, are so compatible with SMT requirement but they usually fail to withstand challenges brought by thermal cycle. As a result, LCC is doubted from the perspective of packaging reliability to interconnection on board, which is because CTE (coefficient of thermal expansion) incompatibility between LCC and PCB material leads to soldering failure. Therefore, ceramic PCBs come into being. Ceramic PCBs are capable of providing optimal solutions for defeating thermal cycle failure because they share compatible CTE with leadless ceramic chip carrier and feature higher thermal conductivity, higher stability and inertia.  | |

| Target State: All States Target City : All Cities Last Update : Jan 20, 2025 9:23 PM Number of Views: 28 | Item Owner : Alisa Contact Email: Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

Hot-Web-Ads > Business Opportunities > Marketing & Sales

© 2025 Hot-Web-Ads.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | USAOnlineClassifieds.com

2025-02-22 (0.221 sec)