Flexible PCB Manufacturer & Assembly Service (Business Opportunities - Marketing & Sales)

Hot-Web-Ads > Business Opportunities > Marketing & Sales

Item ID 15902996 in Category: Business Opportunities - Marketing & Sales

Flexible PCB Manufacturer & Assembly Service | |

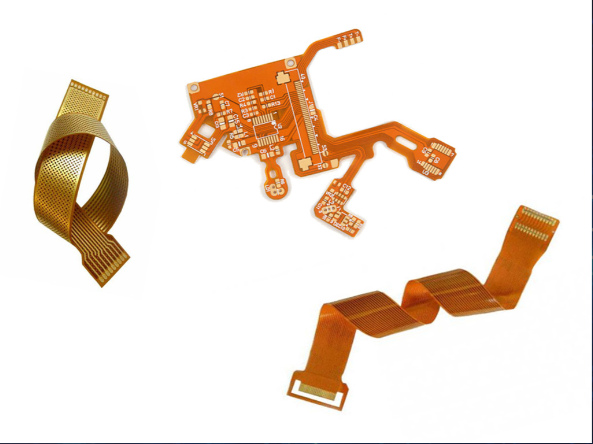

Flexible PCB Manufacturer & Assembly – One-stop services sales12@hitechpcb.com Hitech Circuits Co.,Ltd is a professional flexible pcb, FPC printed circuit board manufacturer, supplier from China, due to its features of bendable, reducing product size, good heat dissipation and solderability, easy assembly and low overall cost etc, it is widely used in mobile phones, wearable smart devices, automobiles, medical treatment, and industrial control etc. If you are looking for a reliable flexible PCB board partner in China, please don’t hesitate to contact sales@hitechcircuits.com Flexible PCB SMT: Technical Points for Mounting Flexible PCB There are many differences between the flexible PCB SMT process and the SMT solution of the traditional rigid PCB. If you want to do the SMT process of the flexible PCB, the most important thing is positioning, because the hardness of the flexible PCB is not enough, it is softer, and if the special carrier is not used, it cannot be fixed and transmitted, and the basic SMT processes such as printing, patch, and furnaces cannot be completed. The key points of pre-processing, fixing, printing, patch, reflux welding, testing, and division plates of flexible PCB in the production of SMT production are specified as below. 1. Flexible PCB pretreatment The flexible PCB is softer, and it is generally not a vacuum packaging when it leaves the factory. It is easy to absorb the water in the atmosphere during the transportation and storage procedures. You need to prepare pre-baking treatment before the SMT patch process and slowly discharge the water, otherwise, under the impact of reflux welding at high temperatures, the water absorbed by the FPC quickly vaporizes into steam, which can easily lead to poor flexible PCB layer departure and foaming. Generally, pre-baking temperatures are 80-100℃ for 4-8 hours, however, under the special condition, the temperature can be raised to more than 125℃, but need to shorten the baking time accordingly. Before baking, be sure to take a small sample test to determine whether the flexible PCB can withstand set baking temperatures, you can also consult flexible PCB manufacturers with appropriate baking process. When baking, don’t put too much flexible PCB for one time, 10-20 panels are more suitable. Some flexible PCB manufacturers may put a piece of paper among each flexible PCB to isolate them and at the same time need to check if the paper can bear the baking temperature, if it cannot be, then pull off the paper before baking. After baking, if the flexible PCB does not have the issues like visible change in color, out of shape, and up warp, etc and then need the IPQC to do sampling inspection. 2. Flexible PCB paste printing The flexible PCB does not have a very special requirement for the ingredients of the weld paste. The size and metal content of the tin ball particles depends on whether there is a fine pitch IC on the flexible PCB, but the printing performance of the solder paste is higher in FPC, welded paste should be easy to print and eliminate modeling and can be firmly stacked to the flexible PCB surface, there will not be adversely obstructing the steel mesh leakage or collapse after printing. Because the flexible PCB is loaded on the carrier plate, the flexible PCB has a high-temperature resistant tape for positioning to make its plane inconsistent, so the printing surface of flexible PCB cannot be as smooth as rigid PCB, and has same thickness and hardness, therefore, it is not suitable to use metal scraper, but should use the hardness of 80-90 degrees of polyurethane scraper. It is best to have an optical positioning system for tin paste printing machine, otherwise it will have a great impact on the quality of printing. Although the flexible PCB is fixed on the carrier, there will always be some small gaps between flexible PCB and the carrier, this is the biggest difference from the rigid board, so the setting of the machine parameters also has a greater impact on printing effects. Printing station is also the key station to prevent flexible PCB dirt, workers need to wear finger stall during operation, at the same time to keep the station clean, and often wipe the steel mesh, to prevent solder paste pollution of the gold finger and gold buttons of flexible PCB.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target State: All States Target City : All Cities Last Update : Jan 22, 2025 3:25 AM Number of Views: 33 | Item Owner : Karen Contact Email: Contact Phone: 18033052358 |

| Friendly reminder: Click here to read some tips. | |

Hot-Web-Ads > Business Opportunities > Marketing & Sales

© 2025 Hot-Web-Ads.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | USAOnlineClassifieds.com

2025-04-19 (0.432 sec)